Data collection and sampling strategy

Structured questionnaires were chosen as data collection method as they allow for collection of comprehensive and comparable information on SFFW in a relatively short time26. Furthermore, the use of survey questionnaires to collect SFFW data is widely spread in the literature due to their ease of distribution and potential to reach large and diverse populations27. As stated by Amicarelli and Bux28 in their research, the majority of studies on SFFW apply questionnaires and surveys as FW measurement methodology28. In addition, the European Commission with the Delegate Decision 2019/1597 has established that the amount of FW within the processing and manufacturing stage of the food supply chain can be assessed through questionnaires and interviews21. Nevertheless, this method carries some limitations especially related to the subjectivity of the respondents20. Eriksson et al.27 point out that questionnaires cannot assess whether the person answering has a clear understanding of the topic or is merely guessing27 and as stated by Amicarelli and Bux28 usually respondents tend to underestimate the amount of waste they create28. However, most of this evidence refers to the household level where many studies showed that questionnaires are not a reliable method to gather FW data29,30,31. Instead, Møller et al.32 confirm that questionnaire is the common methodology used for FW data collection from companies and institutions, especially in larger surveys covering different companies in the food supply chain32. Aware of these considerations, the authors made deliberate efforts to mitigate the limitations of the methodology through the questionnaire design. Control questions were introduced to detect inconsistencies in responses. In particular, questions 5.7, 6.1, and 7.1 were designed to collect cross-verifiable information. These questions report the quantity in volumes of materials recycled or recovered (question 5.7), the amount of disposed waste (question 6.1), and the quantity of products donated (question 7.1). Each of these values was also collected as a percentage over the total production, respectively in question 5.6 for materials recycled or recovered, 6.2 for the amount of disposed waste and 3.2 for the products donated. This allowed to perform internal consistency checks by comparing the quantities in volume with those derived from the production data whose reliability has been demonstrated in section “Technical validation”. These checks have been carried out on a sample basis and it was verified that the responses were coherent in magnitude. It must be also noted that the structure of the questionnaire and the wording of questions were carefully formulated to reduce ambiguity through qualitative interviews and pilot tests conducted before administering the questionnaire. Indeed, to develop a robust initial version of the questionnaire, a qualitative investigation based on case studies was carried out to gain a deeper understanding of how SFFW is generated and managed in the sector. The analysis included 17 cases of interviews with managers from a diverse range of companies to reflect the heterogeneity of the food processing industry. Information was collected on how data related to SFFW is recorded, on the causes of SFFW generation, donation processes and dynamics, and other FW reduction strategies. This exploratory phase informed the selection of measurement units, classifications, and definitions that were familiar to industry professionals in order to ensure clarity and minimize subjective interpretation when filling out the questionnaire as suggested by Møller et al.32. For example, as a result of this activity the definitions of SF, FW, reuse, recovery and recycling have been clarified in the questionnaire and the production quantity has been established as the relevant units of measurement for SFFW estimates. Based on the findings, a preliminary version of the questionnaire was developed and it underwent three rounds of revision. The questionnaire was tested through interviews with managers and industry experts, using a trial-and-error approach in which feedback informed successive refinements. The final version of the questionnaire incorporated all relevant suggestions, with no further changes suggested by the interviewed. Prior to large-scale implementation, additional feedback on the questionnaire’s structure was obtained from the service provider specialized in survey management that administered the questionnaire. To corroborate the reliability of the information collected it must be noted that the data gathered in questions 5.4, 5.6, 5.7, 6.1 and 6.2. overlaps with the information that firms are required to disclose in the mandatory report “Environmental Declaration Form (MUD)” in accordance with the Italian regulatory framework. The communication from the Italian Minister of Environment and Energetic Security (MASE) states that all producers of non-dangerous waste with 10 or more employees are required to draft the MUD and provide information such as the typer of waste, the recycling and recovery practices adopted, and the mass of wastes valorised or sent to disposal33. Since all firms in the sample have to measure and report these information the accuracy of information reported in these questions and in the associated variables can be considered reliable. The resulting survey aimed at representing the population of the Italian food processing sector, excluding the micro-enterprises (less than 10 employees) since small, medium, and large companies themselves contribute to 70% of the overall production25 within the Italian food industry, providing a more accurate reflection of sector trends. In addition, these firms offer more accessible and reliable contextual information compared to micro-enterprises, which lack of detailed records and regulatory filings that hinder consistent and meaningful comparisons. As shown in Table 1, the population of the sample was categorized through three classification variables: the geographical area, the class size, and the product category. The geographical area classifies all the companies in the Italian territory that respect the selection criteria into five macro areas, based on the firm’s HQ address registration. The class size is defined by the number of employees working in the firm, coherently with the Italian and European law (2003/361/CE). The law also contemplates revenues in categorizing the firms by class size but this parameter was not considered in the study due to the unavailability of such information for many firms within our sample. However, the number of employees serves as a straightforward and readily accessible metric for determining firm size34. The product category includes all the enterprises with the main ATECO code related to food industry, which is the Italian equivalent of the NACE classification, the statistical classification of economic activities in the European Community.

Table 1 Classification of the sample.

The total population of Italian companies with at least 10 employees and with ATECO code included between 10.1 and 11.0 is around 8190 firms. Among them, through the survey methodology, it was possible to collect data from 1812 companies, equal to 22% of all Italian food processing firms respecting the sampling criteria. Table 2 shows population’s distribution through the different stratification variables.

Table 2 Stratification of the Italian food processing industry by class size, product category and geographical area according to ISTAT-Asia 202025.

When designing the survey, it was chosen to obtain a sample that was representative of the target population. The sample was selected in 2 steps:

Step 1: the target was set to 1800 companies distributed along the sampling variables (size, product type, and geographical area) according to the criterion of proportionality with the population.

Step 2: the sample has been reproportioned for each classification variable to guarantee a sampling error lower than 12%.

This implies that the obtained sample is non-proportional, but overrepresents the segments (a group of firms homogeneous for one variable) of the population, underrepresenting the larger ones. This sample can be transformed into a proportional sample by weighting the strata (groups of firms homogeneous for all the 3 variables), as explained in the section “Data representativeness”.

The error has been calculated with a conservative approach, assuming the hypothesis of a binary experiment with maximum variability and with a confidence level of 95%. The sample targets have been determined through the following formula35:

$${n}_{i}=\frac{{{z}_{\alpha /2}}^{2}\times N\times {\sigma }^{2}}{{\delta }^{2}\times \left(N-1\right)+{{z}_{\alpha /2}}^{2}\times {\sigma }^{2}}$$

Where:

\(n\) equals to the total population;

\(n\) represents the sample population;

\({\sigma }^{2}\) is the standard deviation of population, assume to be: \(\mathrm{0,5}\cdot (1-\mathrm{0,5})\);

\(\delta \) equals to allowed sampling error;

\(z\) is a value of \(N\left(\mathrm{0,1}\right)\) in a certain range with the confidence value of \(\alpha =95 \% \)

The application of the formula above caused an overestimation of the error.

The reason for introducing reproportioning can be seen in Table 3: the error associated with the segments in the proportional sample is low for some segments (2,2% in small firms) and quite high for others (16,5% in large firms). This error depends on the number of firms observed, so we switch from a purely proportional sampling to a sampling capable of guaranteeing representativeness of the population with an error lower than 12%. As shown in Table 3, all subsamples have a sampling error lower than 12%.

Table 3 Comparison between proportional and non-proportional sample compared to the total population.Survey administration

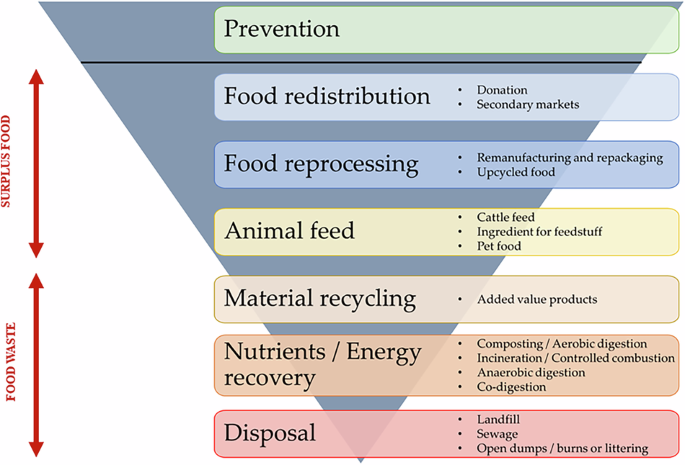

The survey questionnaire has been designed to recall the structure of the theoretical framework proposed in Fig. 1 and therefore it is composed by different sections that refer to the different practices by which SFFW can be valued according to the Food Waste Hierarchy16. As already stated, a first phase of questionnaire testing has been conducted through face-to-face interviews with managers from the Italian food processing sector. The aim of these interviews was the detection and correction of inconsistencies or errors in the questionnaire draft. The three tests have been performed through online interviews. The respondents were managers from large food processing companies in the field of meat processing, fruit and vegetables processing and diary production. All the respondents were asked to answer the questionnaire without researchers’ intervention and were able to do so. They expressed doubts and identified unclear formulations in the questions that were later addressed and corrected by the researchers.

Following the pilot test, data collection through large scale survey was started with the support of experts from Questlab, a survey service provider. The survey has been conducted with the CAWI (Computer Assisted Web Interviewing) methodology, which consists in the collection of data through the compilation of a questionnaire on a website. For this purpose, a web page was designed to collect the answers.

The target respondents of the questionnaire within the company were managers of sustainability, product quality, operations functions or general managers that were considered to have direct knowledge of SFFW management practices within the company. Researchers made sure that the survey was addressed to the most appropriate managerial figure responsible for the management of SFFW within each company through some statements that were inserted in multiple parts of the survey communication: in the presentation letter, the body of the email, and in the preamble of the questionnaire itself. These materials were designed to inform companies on the topic and encourage them to forward the survey to the individual most knowledgeable and responsible for the subject matter. Furthermore, the companies were given the time and flexibility to identify the right respondent and gather the necessary information: the questionnaire was sent through a web link, which allowed respondents to complete it at their own pace and in multiple sessions if needed. In addition, the service provider responsible for administering the survey ensured, through agreed-upon questions via phone interviews, that the questionnaire was directed to the most suitable person within each company. The decision not to pre-assign the questionnaire to a specific role or job title was intentional and based on practical considerations. In many food processing companies, there is often no clearly defined role responsible for the management of SFFW. The relevant responsibilities may vary widely depending on the size, structure, and internal organization of the company. For this reason, it was established to allow each company to identify and delegate the most appropriate respondent internally.

In order to consider a questionnaire valid, it had to be completed for more than 90%. The service provider encouraged the respondents to complete as much as possible the survey through phone calls or email reminders with the aim of reaching the desired sample with relative significance.

When designing the survey it was chosen to achieve a sample that was representative of the entire Italian population of food processing firms, and this strategy of nationwide sampling and sample reproportioning will be described respectively in the sections “Data records” and “Technical validation”.

The questionnaire was launched March 23, 2023, and the last data were filed on June 14, 2023. After obtaining 1812 valid answers, the survey was declared concluded and the collected data were stored in an Excel file.

Subsequently, the data went under manual screening where 14 outliers were identified and consequent checks were made to confirm the soundness of the data provided. Validity checks for outliers were conducted by triangulation with data from websites or company reports available online.

An additional variable was added to the final database obtained after checking for outliers, which corresponds to the imputation of company’s production for the year 2022 described in the section “Technical validation”.

Seven outliers were identified for the variable “production”, the value was rejected after triangulation in 6 cases as not reasonable and substituted with a value obtained with imputation (see the section “Technical validation”). Two outliers were identified for the variable “donation quantity”, one of them led to the removal of the observation after triangulation, the remaining 5 outliers were for the “product category” variable, and led to no removal of data after triangulation. In conclusion, 1 out of 14 identified outliers was removed from the database after triangulation.

Ethical validation

All respondents to the survey were informed of the aims and objectives of the study and consented to open publication of their company’s data as long as they were anonymous (see Section 1 of the questionnaire in the Appendix). For this reason, all identifiable personal information such as name of the company, name of the respondent, tax code, vat number, HQ’s location have been deleted leaving only a completely unidentifiable 8-digit code. In addition, the Ethical Committee of Politecnico di Milano established that the research did not need any IRB approval as no human/personal data was being collected.

Dining and Cooking