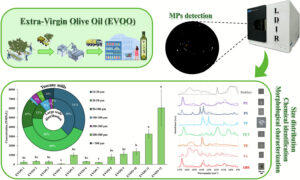

A team of researchers fromUniversity of Florence recently marked a important milestone in the field of food safety, developing and validating the First application of direct laser infrared spectroscopy (LDIR) for the detection of microplastics in extra virgin olive oil (EVOO)The study, published in a prestigious international scientific journal – Food Chemist – introduces an innovative method to address an emerging risk in one of the most complex food matrices to analyze due to its high lipid density.

Until now, identifying contaminants in fatty substances such as oil has posed a significant technical challenge. However, thanks to LDIR technology, it is now possible to simultaneously characterize microplastics in terms of polymer type, size, and morphology, maintaining high data integrity. The effectiveness of this approach is based on an optimized pretreatment protocol that includes solvent dilution, vacuum filtration, and backwashing with ethanol. tests conducted on samples from both Tuscan oil mills and large-scale distribution have confirmed the effectiveness of the procedure, with a particle recovery rate of 95,7%.

A slide from the study produced by the University of Florence

A slide from the study produced by the University of Florence

The analyses revealed the presence of microplastics in all samples examined, allowing the polymer composition and shape of the fragments to be mapped with extreme precision.

In particular, Tuscan olive oils from local mills showed concentrations ranging from approximately 10 to approximately 1.700 particles per liter, with most samples below 350 particles per liter. In contrast, the two supermarket olive oils labeled “produced in the EU” showed much higher levels, ranging from approximately 4.000 to more than 7.900 particles per liter.

While future studies will examine these discrepancies in more depth, Olive Oil Times notes, researchers have suggested that the most likely explanation is the length of the supply chain. Patrizia Pinelli, associate professor of raw materials sciences at the University of Florence and co-author of the study, explained to Olive Oil Times that “NIn large-scale olive oils with an EU origin label, the olives may be harvested in one country and milled in another, or stored for much longer periods. In Tuscany, the transformation from olive to oil usually occurs within 24-48 hours. A longer supply chain naturally increases the chances of contamination.

While future studies will examine these discrepancies in more depth, Olive Oil Times notes, researchers have suggested that the most likely explanation is the length of the supply chain. Patrizia Pinelli, associate professor of raw materials sciences at the University of Florence and co-author of the study, explained to Olive Oil Times that “NIn large-scale olive oils with an EU origin label, the olives may be harvested in one country and milled in another, or stored for much longer periods. In Tuscany, the transformation from olive to oil usually occurs within 24-48 hours. A longer supply chain naturally increases the chances of contamination.

While further, larger-scale studies are needed to establish definitive trends, preliminary findings suggest that manufacturing processes and supply chain management may impact the levels of contamination found.

This discovery has profound implications for the entire extra virgin olive oil supply chain, a symbol of the Mediterranean diet and a cornerstone of the agri-food economy. The introduction of such a sensitive analytical tool offers producers and regulatory bodies a concrete means to ensure transparency and meet growing consumer safety demands. The application of LDIR spectroscopy not only provides a solid scientific basis for future mitigation strategies, but also paves the way for the systematic monitoring of emerging contaminants in fatty foods, promoting increasingly higher quality standards.

No results found.

No results found.

No results found.

Dining and Cooking